-

Address: N0.2555,Xiupu Road, Kangqiao

Industrial Area, Pudong, Shanghai -

Call Us: (+86) 021-51095338

[email protected]

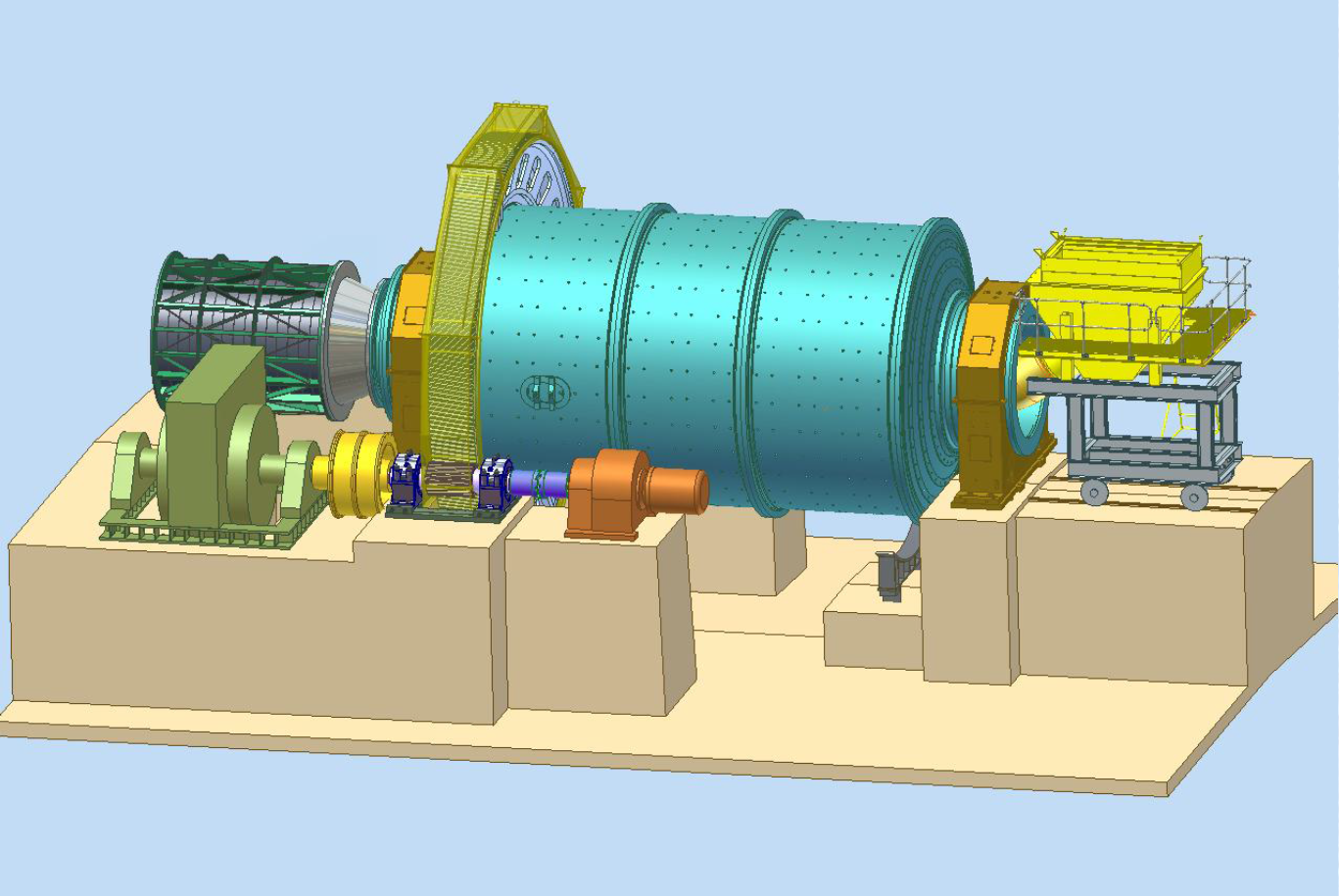

This ball mill is typically designed to grind mineral ores and other materials with different hardness, and it is widely used in different fields, such as ore dressing, building material field, chemical industry, etc. Due to the difference of its slurry discharging method, it is divided to two types: grid type ball mill and overflow type ball mill.

Compared with grid type ball mill, overflow type ball mill can grind materials finer even though its grinding time is usually longer. So it can make finer particle products. Hence the grid type ball mill is mainly used for primary stage of grinding while overflow type ball mill is mainly used for the secondary grinding.

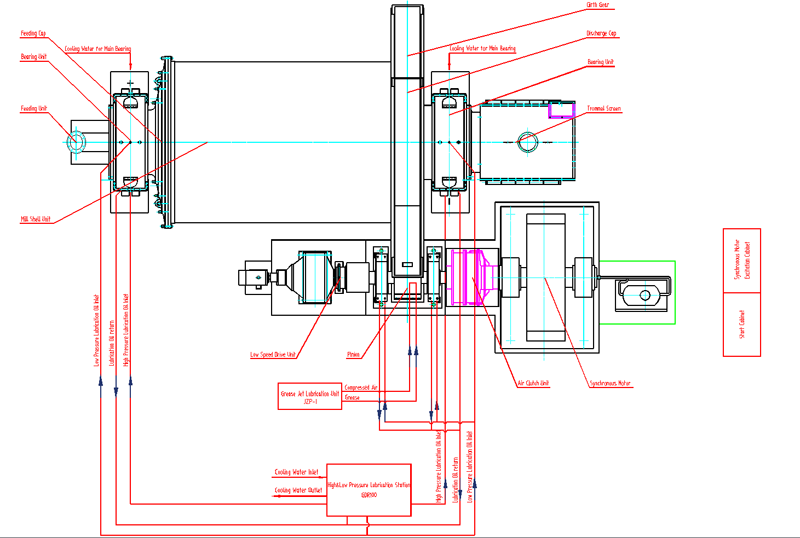

Ball mill Structure:

Ball mill Advantages:

1、Jack-up device, easy maintenance;

2、The hydrostatic and hydrodynamic bearings ensure the smooth operation;

3、Low speed transmission is easy for starting and maintenance;

4、The oil-mist lubrication device guarantees reliable performance of bearings;

5、The air clutch adopts the flexible start-up model./5According to the customer demand, manganese steel liner and wear-resistant rubber liner can be customized with good wear resistance, long service life and easy maintenance.

Working Principle of Ball mill:

As the mill rotates, steel balls work to grind the materials. The mill rotates approximately once every couple of seconds.

The grinding system uses either 'open circuit' or 'closed circuit'. In an open circuit system, the feed rate of materials is adjusted to achieve the desired fineness of the product. In a closed circuit system, coarse particles are separated from the finer ones and sent back for further grinding.

When final products reach the fineness standard, they are discharged out of the mill.

Ball mill of Technical Specifications:

| Model | Shell Size | E-Volume | Ball Load | R-Speed | Power | Output Size | Capacity | Remark |

| D×L(mm) | (m3) | (t) | (r/min) | (kw) | (mm) | (t/h) | ||

| MQG2136 | 2100×3600 | 11 | 19 | 23.8 | 210 | 0.3-0.074 | 29-6.5 | 380V |

| MQG2430 | 2400×3000 | 12.2 | 25 | 22.8 | 250 | 0.3-0.074 | 38-7.5 | 380V |

| MQG2436 | 2400×3600 | 14.6 | 30 | 22.8 | 280 | 0.3-0.074 | 42-8.5 | 380V |

| MQG2445 | 2400×4500 | 18.2 | 37 | 22.8 | 400 | 0.3-0.074 | 55-10.5 | 6-10KV |

| MQG2721 | 2700×2100 | 10.7 | 24 | 21.7 | 280 | 0.3-0.074 | 84-8.5 | 6-10KV |

| MQG2730 | 2700×3000 | 15.3 | 32.5 | 21.7 | 355 | 0.3-0.074 | 120-10 | 6-10KV |

| MQG2736 | 2700×3600 | 18.4 | 39 | 21.7 | 400 | 0.3-0.074 | 145-12 | 6-10KV |

| MQG2740 | 2700×4000 | 20.5 | 43 | 21.7 | 450 | 0.3-0.074 | 159-13 | 6-10KV |

| MQG2745 | 2700×4500 | 23 | 50 | 21.7 | 500 | 0.3-0.074 | 180-15 | 6-10KV |

| MQG3245 | 3200×4500 | 32.8 | 65 | 18.6 | 710-800 | 0.3-0.074 | 235-29 | 6-10KV |

| MQG3254 | 3200×5400 | 39.2 | 81.6 | 18.6 | 800-1000 | 0.3-0.074 | 280-35 | 6-10KV |

| MQG3645 | 3600×4500 | 40.8 | 88 | 17.3 | 1000 | 0.3-0.074 | 259-29 | 6-10KV |

| MQG3650 | 3600×5000 | 45.3 | 96 | 17.3 | 1120 | 0.3-0.074 | 288-35 | 6-10KV |

| MQG4040 | 4000×4000 | 45 | 82 | 16.4 | 1000 | 0.3-0.074 | 230 | 6-10KV |

| MQG4050 | 4000×5000 | 57 | 161 | 16.4 | 1250 | 0.3-0.074 | 270 | 6-10KV |

| MQG4560 | 4500×6000 | 85 | 162 | 15.42 | 2000 | 0.3-0.074 | 285 | 6-10KV |

| Note:The ball mill model can be customized according to demands. | ||||||||

| Model | Shell Size | E-Volume | Ball Load | R-Speed | Power | Output size | Capacity | Remark |

| D×L(mm) | (m3) | (t) | (r/min) | (kw) | (mm) | (t/h) | ||

| MQY2136 | 2100×3600 | 11 | 19 | 23.8 | 210 | 0.8-0.074 | 28-6.0 | 380V |

| MQY2430 | 2400×3000 | 12.2 | 23 | 22.8 | 250 | 0.8-0.074 | 34-6.6 | 380V |

| MQY2436 | 2400×3600 | 14.6 | 25 | 22.8 | 280 | 0.8-0.074 | 40.5-7.9 | 380V |

| MQY2445 | 2400×4500 | 18.2 | 31 | 22.8 | 355 | 0.8-0.074 | 50-9.8 | 380V |

| MQY2721 | 2700×2100 | 10.7 | 20 | 21.7 | 280 | 3.0-0.074 | 76-6.0 | 380V |

| MQY2730 | 2700×3000 | 15.3 | 28 | 21.7 | 355 | 3.0-0.074 | 108-8.8 | 380V |

| MQY2736 | 2700×3600 | 18.4 | 34 | 21.7 | 355-400 | 3.0-0.074 | 130-10.5 | 380V |

| MQY2740 | 2700×4000 | 20.5 | 37 | 21.7 | 400-450 | 3.0-0.074 | 144-11.5 | 6-10KV |

| MQY2745 | 2700×4500 | 23 | 42.5 | 21.7 | 500 | 3.0-0.074 | 180-13 | 6-10KV |

| MQY3245 | 3200×4500 | 32.8 | 61 | 18.6 | 630 | 3.0-0.074 | 228-22 | 6-10KV |

| MQY3254 | 3200×5400 | 39.3 | 73 | 18.6 | 710 | 3.0-0.074 | 270-20 | 6-10KV |

| MQY3645 | 3600×4500 | 40.8 | 76 | 17.3 | 800-1000 | 3.0-0.074 | 233-26 | 6-10KV |

| MQY3650 | 3600×5000 | 45.3 | 86 | 17.3 | 1120 | 3.0-0.074 | 260-31.5 | 6-10KV |

| MQY4564 | 4500×6400 | 85 | 174 | 14.54 | 2000 | 3.0-0.074 | 158 | 6-10KV |

| MQY4570 | 4500×7000 | 111 | 190 | 15.6 | 2500 | 3.0-0.074 | 168 | 6-10KV |

| MQY5080 | 5030×8000 | 145 | 240 | 14.2 | 3500 | 3.0-0.074 | 250 | 6-10KV |