-

Address: N0.2555,Xiupu Road, Kangqiao

Industrial Area, Pudong, Shanghai -

Call Us: (+86) 021-51095338

[email protected]

STL-100(80)A large-scale centrifugal concentrating equipment adopts PLC electrical control system to cooperate the feeding device, water supply device and discharge device working together to realize equipment automatic Production. The recoil water and ore discharge are carried out at the same time, which shortens the equipment work cycle and improves the production capacity. In addition, the equipment has a high degree of automation and is easy to install and maintain. The enrichment cone adopts polymer wear-resistant materials to increase the service life of the equipment and reduce the cost of the equipment.

Centrifugal Concentrator Working principle

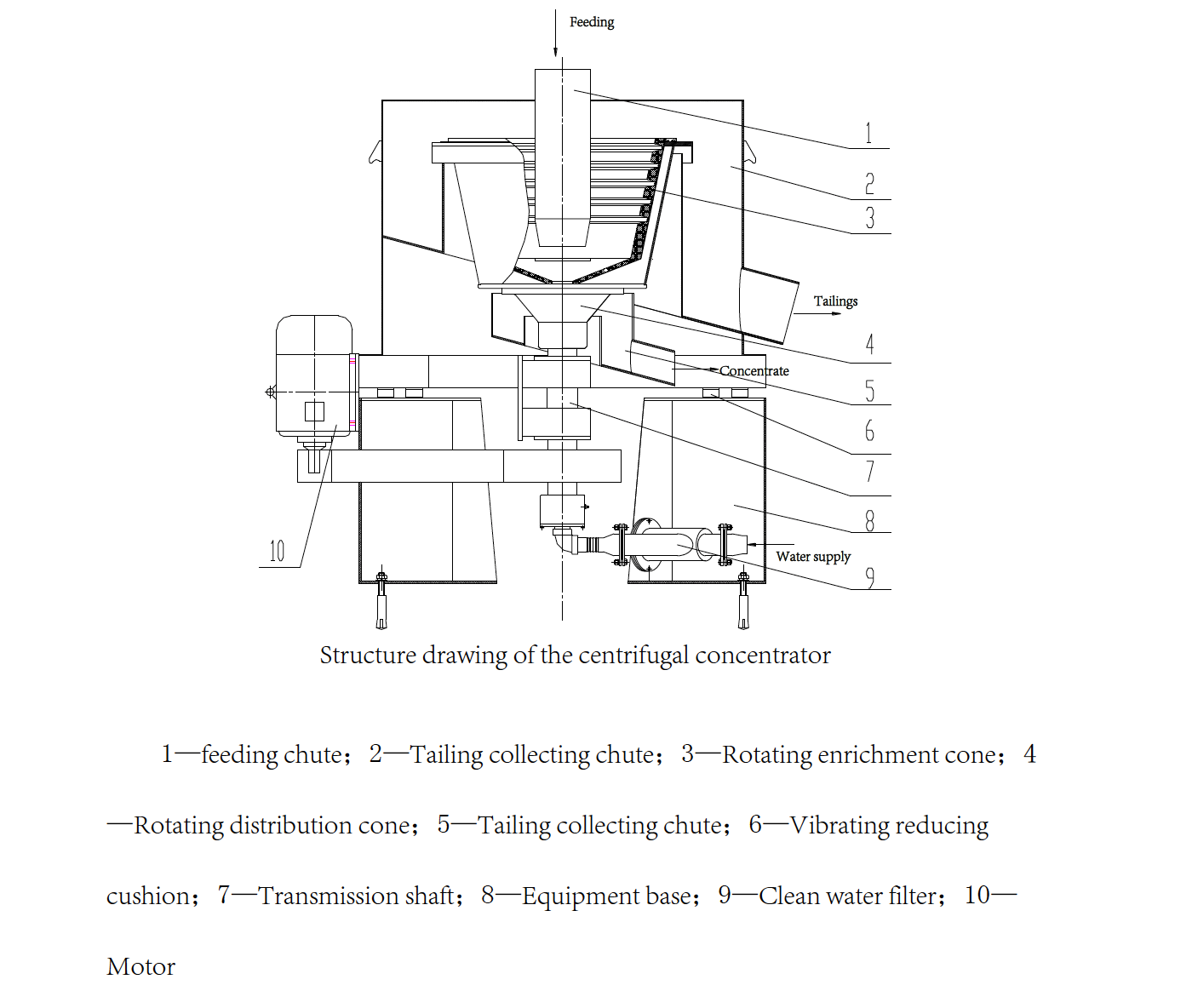

The STL-100(80)A centrifugal concentrator is a gravity separation equipment based on the density of minerals. It produces different moving speeds and trajectories through the density and particle size of different materials to achieve the purpose of separation.

While the minerals are fed into the enrichment cone of the centrifugal concentrator through the ore supply device, clean water enters the enrichment cone from the drive shaft for backwashing mineral separation operations. After the separation operation is completed, the concentrate enters the rotation through the discharge port at the bottom of the enrichment cone, then it is discharged from the rotating distribution cone to the concentrate collection hopper. The tailings are discharged from the upper part of the enrichment cone to the tailings collection bucket under the action of centrifugal force.

Outline drawings of STL-100(80)A series Centrifugal concentrator

Centrifugal Concentrator Technical Specifications:

| Model | STL-100A | STL-80A |

| Feeding pulp density (%) | 15-35 | 15-30 |

| Max feeding size (mm) | <6 | <4 |

| Optimal feeding size (mm) | 1.7 | 1.7 |

| Time setting (h) | 0-4 | |

| Capacity (t/h) | 100-200 | 30-60 |

| Dimension (mm) | 2280×1750×2400 | 1980×1600×2350 |

| Weight (t) | 3.5 | 2.4 |

| Motor power (kw) | 30 | 15 |