-

Address: N0.2555,Xiupu Road, Kangqiao

Industrial Area, Pudong, Shanghai -

Call Us: (+86) 021-51095338

[email protected]

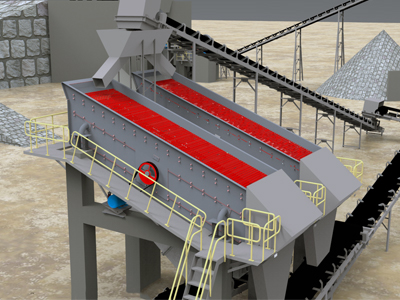

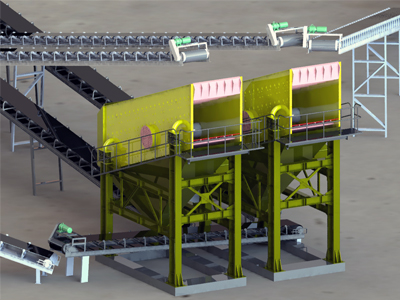

The vibrating screen is a kind of sieving equipment of international advanced technology. Its uniquely robust deck frames are an example of its enhanced durability and reliability. The shaft line is positioned at the center of gravity, a perfect circular motion results on all points on the screen. Combined with an adjustable slope angle from 12-22° this circular motion gives very good screening efficiency for all types of applications, such as primary, technical and final screening. It is widely used for grading and screening materials in the following fields: minerals, quarry, building materials, water conservancy and hydropower, transportation, chemical industry, smelting and so on

Vibrating Screen Features:

1)Easy adjustability of stroke & speed

2)Modular vibrators and cardan shaft design

3)Easy access and quick replacements of screening media

4)vibrators: long bearing life, (double bearing design)

5)Weld free side plates and huck-bolted assembly

Vibrating Screen Working Principle:

A vibrating screen is a device that uses rubber springs as supporting elastic elements, and an exciter as a vibration source. The vibration force is generated by the rotation of the eccentric block, which causes the screen box to generate a circular reciprocating motion. The material continuously makes a round and bouncing motion on the inclined screen surface. By repeatedly comparing with the screen hole, the material smaller than the screen size passes through the screen, and the material larger than the screen size is on the screen surface to complete the screening process.

Vibrating Screen Technical Parameters:

| Model | Deck dimension (mm) | Decks | Leaning angle of screen (℃) | Top deck max.opening (mm) | Maximum feed size (mm) | Speed (r/min) | Double amplitude (mm) | Capacity (t/h) | Power (kw) | Overall dimension (mm) |

| 2Y1237 | 1200×3700 | 2 | 20 | 3-50 | 200 | 970 | 8 | 7.5-80 | 15 | 4010×2250×2660 |

| 3Y1237 | 1200×3700 | 3 | 20 | 3-50 | 200 | 970 | 8 | 7.5-80 | 15 | 4010×2250×3140 |

| 2Y1548 | 1500×4800 | 2 | 20 | 5-50 | 400 | 970 | 8 | 50-208 | 15 | 5120×2590×3060 |

| 3Y1548 | 1500×4800 | 3 | 20 | 5-50 | 400 | 970 | 8 | 50-250 | 15 | 5120×2590×3540 |

| 2Y1848 | 1800×4800 | 2 | 20 | 5-80 | 400 | 970 | 8 | 50-260 | 18.5 | 5120×2950×3060 |

| 3Y1848 | 1800×4800 | 3 | 20 | 5-80 | 400 | 970 | 8 | 50-300 | 18.5 | 5120×2950×3540 |

| 2Y1860 | 1800×6000 | 2 | 20 | 5-80 | 400 | 970 | 8 | 50-300 | 18.5 | 6260×2950×3480 |

| 3Y1860 | 1800×6000 | 3 | 20 | 5-80 | 400 | 970 | 8 | 50-350 | 22 | 6260×2990×3960 |

| 2Y2160 | 2100×6000 | 2 | 20 | 5-150 | 400 | 730 | 6-8 | 100-500 | 22 | 6270×3410×3670 |

| 3Y2160 | 2100×6000 | 3 | 20 | 5-150 | 400 | 730 | 6-8 | 100-500 | 30 | 6270×3470×4100 |

| 2Y2460 | 2400×6000 | 2 | 20 | 5-150 | 400 | 730 | 6-8 | 150-700 | 37 | 6270×3770×3610 |

| 3Y2460 | 2400×6000 | 3 | 20 | 5-150 | 400 | 730 | 6-8 | 150-700 | 37 | 6270×3790×4100 |